Category

Materials synthesis and treatment; Cleanrooms

Manufacturer and Model

Sidrabe - SAF25/50

Specifications

- Substrate: glass, metal, plastic, ceramic

- Substrate size: 25 x 25 or 50 x 50 mm

- Substrate temperature: - 40 … + 400ºC (depends on the process)

- Base pressure: 1·10-7 Torr

- Installed power: 50 kW

Applications and capabilities

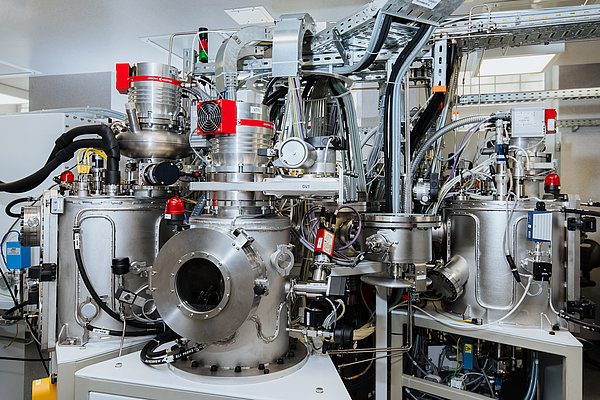

The SAF25/50 multifunctional R&D cluster tool is intended for research and development works as well as for feasibility studies and more general academic work in the field of thin film technologies.

The tool is a multifunctional, expandable, modular and flexible system. The tool comprises an input/output chamber with ion gun, central substrate transfer chamber with radial telescopic transport arm and up to 7 deposition chambers. Substrate is positioned horizontally on a holder. Deposition zones are configured for substrate rotation or displacement during upward deposition.

Tool multifunctionality and flexibility is founded on the following key features:

- Each chamber can operate independently due to individual pumping means, controls and utility connections.

Deposition chambers and deposition sources are interchangeable. - The central transfer chamber prevents process cross-contamination and ensures substrate transfer without venting of the chambers.

- Various types of deposition sources including sublimation thermal cells, resistive boats, crucibles and sputter magnetrons can be integrated.

- Twin, single and dual sputter magnetrons can be powered by DC, pulsed DC, MF and RF power supplies.

Contact and contactless cooling and heating of the substrate is offered. - Glove box for substrate loading in inert gas atmosphere and substrate magazine can be added.

- Preliminary agreed number of blanked-off flanges installed on the chambers allows attaching customized instrumentation and technological accessories.

- Basic configuration of the pumping system includes turbomolecular and two-stage dry mechanical pumps.

The control system can operate in a semi-automatic and manual mode.