Identification number: lzp-2022/1-0454

Type: Fundamental and applied research project of the Latvian Council of Science

Project duration: 04.2023 - 03.2026

Project manager: Dr.Phys. Martins Zubkins, Institute of Solid State Physics, University of Latvia

Total funding: 300 000 EUR

Project aim:

To develop advanced deposition technology of metal hydride and borohydride films, and study the influence of growth process parameters on the thin film structure and properties.

Project summary:

Reactive High Power Impulse Magnetron Sputtering (r-HiPIMS) deposition technology has a huge potential for manufacturing coatings with properties exceeding those of state of the art. The available research activities have mainly been the HiPIMS deposition of metals (Ar plasma), metal oxides by reactive process (Ar+O2), and metal nitrides (Ar+N2), but deposition of metal hydrides (Ar+H2) has not yet been demonstrated. Metal hydrides (MHx) and boro-hydrides M(BH4)x are a fascinating and important class of materials that can be used for storage and other energy applications, as far as Hydrogen storage will be a key technology for energy utilization in the 21st century. Also, lanthanide hydrides (LnHx) are unique classes of materials with a rich spectrum of physical properties. The project proposes to produce MHx and M(BH4)x (M: alkali-earth Mg, transition metals Ti and Y, lanthanides La and Eu) in the thin film form by r-HiPIMS and do in-depth characterisation by advanced in-lab techniques – XRD, XPS, SEM, TEM, Raman and UV-Vis-NIR spectroscopy, and spectroscopic ellipsometry. The project aims to study the relationship between the HiPIMS deposition parameters (impulse durations, sputtering power, pressure, substrate temperature) and chemical composition, properties, structure and density. HiPIMS sputtering has been chosen as the deposition technique since it is widely used in both lab-scale and industry with possible up-scaling.

ON THE IMPLEMENTATION OF THE PROJECT (PERIOD 01.04.2025. - 30.06.2025.)

During the given period, yttrium oxyhydride (YHO) thin films were deposited using the reactive pulsed DC magnetron sputtering method, while varying the deposition atmosphere at elevated temperature (200 °C). This series of samples was analysed to evaluate the influence of the partial hydrogen pressure on the structure, optical, and photochromic properties of the thin films. X-ray diffraction results indicate that the crystallite orientation depends on the partial hydrogen pressure – when it increases, the predominant crystallite orientation shifts from the (100) to the (111) crystallographic direction. In addition, a correlation was observed between the hydrogen flow during the process and the photochromic contrast of the coatings after irradiation with a solar simulator.

Based on the obtained knowledge of the dependence of crystallite orientation on hydrogen flow, a new series of samples was initiated on single-crystal substrates with different orientations: YSZ (yttria-stabilised zirconia) (111) and (100), as well as CaF₂ (111) and (100).

On 1 June, the second article from this project, Role of hydrogen dynamics and deposition conditions in photochromic YHO/MoO₃ bilayer films (Fig. 9), was published in Solar Energy Materials & Solar Cells 292 (2025) 113789. The study was carried out in collaboration with the Ångström Laboratory, Uppsala University.

From 18 to 20 June, the international SWEB Hybrid Summer School SOLAR ENERGY MATERIALS AND SMART DEVICES took place at the Institute of Solid State Physics. Within its framework, M. Zubkins delivered a lecture Photochromism of YHO/MoO3. He also conducted a practical training session on YHO magnetron sputtering and photochromic effect measurements.

ON THE IMPLEMENTATION OF THE PROJECT (PERIOD 01.01.2025. - 30.04.2025.)

During the relevant time period, , we developed thin films combining photochromic and antimicrobial properties using roll-to-roll (R2R) reactive magnetron sputtering – a scalable industrial technique. The coatings consist of oxygen-containing yttrium hydride (YHO) and bilayer structures with an additional copper layer, deposited on flexible plastic substrates.

The films were analysed to assess their crystal structure, morphology, and optical behaviour. Under UV–violet light, the films exhibited reversible darkening and returned to their initial state in the absence of illumination. The surface modification with copper was investigated as a means to introduce antimicrobial functionality while maintaining optical performance.

Initial testing suggests that these multifunctional coatings hold promise for applications such as smart windows and self-disinfecting surfaces, combining passive light regulation with surface hygiene enhancement. The study demonstrates the feasibility of scaling up YHO-based films for large-area use. A scientific article on this research is currently in preparation.

On 7 January, the Latvian Council of Science approved a new research proposal titled “Development of scalable deposition technologies for next-generation mixed-anion thin films”, No. 1.1.1.9/LZP/1/24/011 (PostDoc Latvia), which will ensure the continued development of the results and knowledge gained in the current project.

On 29 January, the article Vibrational properties of photochromic yttrium oxyhydride and oxydeuteride thin films was published (see Figure 8) in the Journal of Alloys and Compounds, 1015 (2025) 178917. The research was carried out in collaboration with the Latvian Institute of Organic Synthesis.

On 29 January and 18 February, M. Zubkins presented the latest project results at the scientific seminar Thin Films & Low-Dimensional Structures (ISSP UL) and at the SWEB project Coordination and Steering meeting, respectively. On 11 February, he gave an online poster presentation titled “Photochromic oxygen-containing yttrium hydride (YHO) and YHO/MoO3 coatings: synthesis, structural analysis, and hydrogen diffusion studies” at the 1st International Conference on Hydrogen in Materials Science and Engineering (H2 MSE).

On 4 March, E. Letko and E. Strods presented at the annual ISSP conference with talks titled “Deposition of photochromic YHO thin films by magnetron sputtering and their characterization” and “Optical and photochromic properties of YHO/MoO3 thin films”, respectively.

ON THE IMPLEMENTATION OF THE PROJECT (PERIOD 01.10.2024. - 31.12.2024.)

During the respective time period, several series of yttrium oxyhydride thin film samples were fabricated, in which the sputtering atmosphere conditions were varied. The coatings were deposited on glass and silicon using a reactive pulsed direct current (pulsed-DC) magnetron sputtering mode. To achieve more precise control over the sputtering process and improve the reproducibility of the sputtered coatings, optical emission spectrophotometry was integrated into the magnetron sputtering system. The photochromism, structure, and optical properties of the sputtered thin films were investigated using X-ray diffraction, ellipsometry, optical spectrophotometry, and a custom-built system for measuring photochromic properties.

After optimization, changes in the microstructure and photochromic properties were observed, including enhanced coloration of the coatings and improved contrast. The observed microstructural changes correlate with variations in the photochromic properties.

On 7 November, M. Zubkins delivered a presentation titled “Magnetron sputtering deposition and characterisation of photochromic yttrium oxyhydride and Ga-based oxide thin films” at the SWEB project Industry Day on advanced smart windows.

On December 12, E. Strods attended the RSD 2024 international conference, which took place in Ghent, Belgium. During the conference, a poster presentation titled “Optical and photochromic properties of yttrium oxyhydride thin films deposited by reactive magnetron sputtering” was presented, showcasing the results obtained in this project. This presentation was awarded the "Best Poster Presentation" prize (Figure 7). During the conference, new contacts were established with representatives from the companies "Solares" and "Robeko", as well as with researchers from Ghent University and the University of West Bohemia.

ON THE IMPLEMENTATION OF THE PROJECT (PERIOD 1.07.2024. - 30.09.2024.)

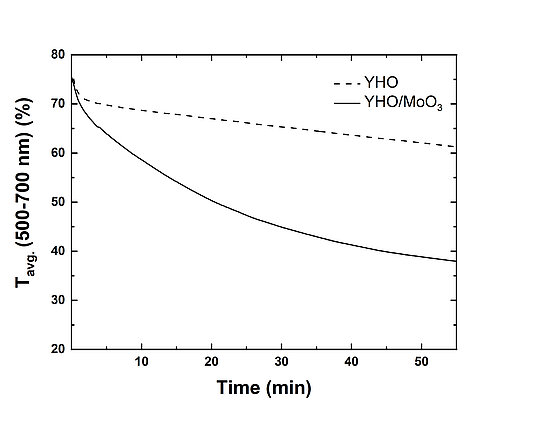

During the specified time frame, several series of samples were produced by combining yttrium oxy-hydride (YHO) and molybdenum trioxide (MoO3) thin films. In these sample series, the sputtering parameters of the MoO3 thin film - deposition time, operating pressure, and oxygen flow rate - were varied. The coatings were deposited on two types of substrates, glass and silicon, with both YHO and MoO3 deposited in reactive pulsed-DC magnetron sputtering mode. The photochromism, composition, structure, and optical properties of the deposited thin films were investigated using X-ray diffraction, scanning electron microscopy, optical spectrophotometry, ellipsometry, profilometry, X-ray photoelectron spectrometry, and a self-built system for measuring photochromic properties. The results show a synergistic effect between the YHO and MoO3 layers that enhances the photochromic mechanism. The parameters of the MoO3 layer - thickness, density, and the amount of oxygen vacancies - significantly influence the UV-induced light absorption of the YHO/MoO3 structure. Figure 6 shows that the combined YHO/MoO3 coating has a significantly enhanced UV-induced coloration rate compared to uncoated YHO. Both coatings (YHO and YHO/MoO3) exhibit similar initial light transmittance (≈ 75%). These results formed the basis for the submission and defense of a Master's thesis.

ON THE IMPLEMENTATION OF THE PROJECT (PERIOD 01.04.2024. - 30.06.2024.)

A new series of yttrium oxyhydride (YHO) thin film samples was produced on glass substrates, varying the production temperature between room temperature and 400°C. It has been found that the substrate temperature significantly alters the optimal parameters, which ensure high-quality photochromic properties – such as high photochromic contrast and fast bleaching rate. Research is ongoing to determine whether the production temperature has a substantial effect on the photochromic properties at the optimal manufacturing parameters. Samples have undergone X-ray diffraction (XRD) and optical spectroscopy measurements (UV-Vis-NIR), as well as irradiation with a solar simulator to obtain quantitative values of the photochromic effect. Students from Riga State Gymnasium No. 1 have joined this activity to develop a scientific research project.

On 7 May, an oral talk titled “Yttrium oxyhydride thin films: synthesis, optical, and photochromic properties” was presented on the results obtained from this project at the international scientific and technical conference TechCon 2024, in Chicago, USA (Figure 5).

On 3 and 4 June, within the framework of the international summer school at ISSP UL “Advanced Materials for Chromogenic Device Applications and Thin Films: Synthesis and Characterization”, M. Zubkins gave a lecture “Physical vapour deposition (PVD) method: Magnetron Sputtering” and led laboratory work.

On 10 June, E. Letko successfully defended (grade 10) their Bachelor's thesis titled “Deposition of photochromic YHO thin films by magnetron sputtering and their characterization” at the University of Latvia, Faculty of Physics, Mathematics and Optometry, Department of Physics.

A scientific article on the vibrational studies of YHO and deuterium-labelled YDO thin films has been submitted.

ON THE IMPLEMENTATION OF THE PROJECT (PERIOD 01.01.2024. - 30.03.2024.)

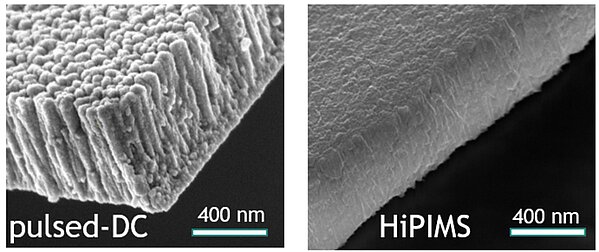

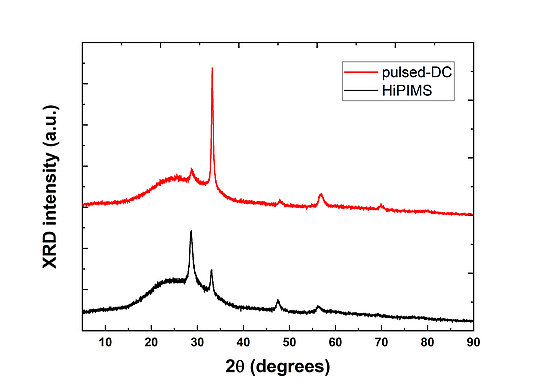

During the relevant time period, YHO thin films were deposited under different sputtering pressures (3, 5, and 9 mTorr) using various modes: pulsed-DC, HiPIMS without substrate biasing, and HiPIMS with different substrate bias configurations (synchronized bias). The average energy of the ions bombarding the growing film is directly proportional to the electric potential difference between the substrate and the plasma. This means that the ion energy and the microstructure of the thin film can be adjusted by modifying the substrate bias. As mentioned above, the choice between HiPIMS or pulsed-DC mode for depositing YHO thin films significantly influences their structure (see Figure 4) and photochromic properties. There are several types of bias voltage configurations because metal ions and gas ions are not generated simultaneously in the HiPIMS discharge. At the beginning of a high-power pulse, the number of gas ions increases almost instantly, while the number of metal ions rises after some delay. Eventually, the concentration of metal ions exceeds that of gas ions due to gas rarefaction. To most effectively apply the substrate bias voltage, it is necessary to synchronize it with the HiPIMS discharge pulses, allowing the acceleration of specific ions. In this study, samples were produced using the following bias configurations: DC bias, bias synchronized with the HiPIMS pulse, and bias time-shifted by half a phase. The microstructure of the obtained thin films was studied over seven days using X-ray diffraction (XRD).

During the relevant period, different series of samples - YHO in pulsed-DC and HiPIMS modes, YHO/MoO3, and YHO at elevated temperatures - were prepared for compositional measurements, which were carried out at Uppsala University Tandem Laboratory.

On 11 March, M. Zubkins presented results on YHO HiPIMS films at the online seminar HiPIMS Today 2024.

On 19th January, E. Strods successfully defended his Master's thesis with distinction (grade 10) titled "The effect of MoO3 film on the UV-induced light absorption of YHO/MoO3 structure" at Riga Technical University, Faculty of Mechanical Engineering, Transport and Aeronautics, Institute of Biomedical engineering and nanotechnology.

ON THE IMPLEMENTATION OF THE PROJECT (PERIOD 01.10.2023. - 31.12.2023.)

During the respective time period, we prepared thin films of yttrium oxyhydride (YHO) and its deuterium-labelled counterpart (YDO) using reactive magnetron sputtering, followed by a controlled oxidation step. These photochromic materials change their transparency when exposed to light, making them promising candidates for smart window applications.

To understand their structure and behaviour, we used a range of advanced techniques including X-ray diffraction (XRD), solid-state nuclear magnetic resonance (ssNMR), and Fourier-transform infrared (FTIR) spectroscopy. FTIR measurements, conducted for the first time in the far-infrared region for these films (see Figure 3), revealed broad vibration bands, indicating a high level of structural disorder. By replacing hydrogen with deuterium, we could clearly identify the specific vibrations involving hydrogen atoms.

Our observations, supported by theoretical calculations, confirmed that the films consist of nanocrystalline cubic phases with local variations in composition and bonding environments. When exposed to ultraviolet light, the films showed increased infrared absorption without undergoing structural changes. These findings help clarify the vibrational and photochromic properties of YHO-based materials and support the development of next-generation light-responsive coatings.

ON THE IMPLEMENTATION OF THE PROJECT (PERIOD 01.07.2023. - 30.09.2023.)

During the specified time frame two series of yttrium oxyhydride thin films were deposited: in the r-HiPIMS mode and in the reactive pulsed-DC magnetron sputtering mode. The coatings were made on two types of substrates: glass and silicon. Yttrium oxyhydride thin films were obtained by sputtering YH2 thin films in a reactive atmosphere (Ar+H2) from an yttrium target and oxidized in air after the process. For both series, sputtering parameters were found which allow to obtain transparent coatings with a structure corresponding to YHO and which exhibit a photochromic effect after irradiation with ultraviolet light. HiPIMS mode requires higher pressure than pulsed-DC. Changes in optical properties over time were observed with the spectrometer, indicating the continuation of oxidation of the thin films, changes in composition and structure several days after the process. The influence of the selected sputtering mode and sputtering parameters (pressure, time, temperature) on the structure of thin films (crystallite size, lattice parameter) and optical properties (transmittance, optical band gap) was investigated. The X-ray diffractograms of the YHO films made in r-HiPIMS mode at a sputtering pressure of 8.5 mTorr and in pulsed-DC mode at a pressure of 5.1 mTorr are shown in Figure 2. The thicknesses of both coatings is about 550 nm. The photochromic properties (photochromic contrast, bleaching time) of the thin films were evaluated by periodically illuminating them with ultraviolet light and measuring the change in transmittance. To evaluate and compare the effect of the two methods on the delamination rate of the coatings, the surface changes of the thin films over time are observed with an optical microscope.

ON THE IMPLEMENTATION OF THE PROJECT (PERIOD 01.04.2023. - 30.06.2023.)

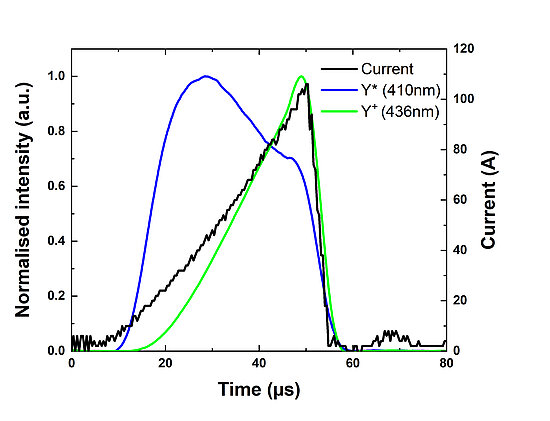

During the specified time frame, a vacuum physical vapour deposition system was successfully prepared to realize reactive high power impulse magnetron sputtering (r-HiPIMS). The system is equipped with balanced magnetrons and the necessary process gases – Ar and H2. We conducted preliminary experiments on an yttrium (Y) target by sputtering the target in both inert (Ar) and reactive (Ar+H2) atmospheres. Our system is equipped with a HiPIMS power source, alongside a high time-resolved spectrometer to detect changes in plasma emission line intensities during a pulse. Figure 1 shows an example of the change in emission intensities of excited Y atoms (Y*) and ions (Y+) during a 50 µs sputtering pulse. Both the discharge current peak value of 105 A and the intense Y+ emissions correspond to the HiPIMS mode. Emission line intensity directly depends on the concentration of relevant particles in the plasma and provides essential information for further process optimization. We successfully deposited the first thin films of yttrium hydride (YH2) and yttrium oxyhydride (YHO) on glass substrates using the r-HiPIMS process.

A comprehensive study of the vibrational properties, exploring the structure and the photochromic effect, of YHO and anion-labelled oxydeuteride (YDO) thin films has been initiated.