M-Era.net project acronym: INNOHYPPY

Project duration: 01.06.2023. – 31.05.2026.

Project Manager – Dr. Šarūnas Varnagiris, Lithuanian energy institute, Lithuania

Partners:

- Institute of Solid State Physics, University of Latvia;

- Jožef Stefan Institute (Slovenia)

Responsible person from ISSP UL – Dr. Līga Grīnberga

Total funding: 543 888 euro

ISSP UL part: 183 888 euro

Project Aim:

Fundamental and practical investigation of Fe/Ni materials by development of novel catalyst for cleaner and more efficient clean hydrogen production via methane pyrolysis technique as well as their regeneration in order to increase its durability, where all the residues will be used as secondary raw materials for further application.

Project Summary:

According to the Sustainable Development Goal on Energy (SDG7) as well as Green Deal, RePowerEU and other EU initiatives, clean energy solutions are essential to counter climate change, one of the biggest threats to our own survival. To reach ambitious EU goals, the development of advanced materials, which could be applied in a field of clean energy production and utilization will play a key role. Moreover, it is generally agreed that hydrogen energy development is a priority for a clean and circular economy as well as a reduction of greenhouse gas (GHG) emissions.

In this project, novel catalyst development activities will be initiated for clean hydrogen production via pyrolysis technique as well as experiments of catalyst material regeneration in order to extend its lifetime while all the residues will be used as secondary raw materials for further application. Specifically, instead of existing methods, gamma alumina support for Fe/Ni catalyst deposition will be prepared in an innovative way, using a direct modified aluminium-water reaction based on the Lithuanian energy institute EPO patent. The magnetron sputtering technique will be used for the synthesis of Fe with widely dispersed Ni nanoclusters on gamma alumina. The systematic investigation of the methane pyrolysis process using a synthesised catalyst and finding the optimal reactor of methane pyrolysis design will be implemented. Novel regeneration by plasma treatment of deactivated catalyst after the pyrolysis process will be performed. Finally, the evaluation of pyrolysis reaction by-product (solid carbon) properties and original application for preparation of carbon-based electrode used for detection of pesticides will be initiated. The general start and the target TRL of mentioned project activities is between TRL 2 and TRL 4, respectively.

The project reflects the impacts, which are expected to reach ambitious goals related to climate change including energy conversion, higher efficiency with improved overall performance, avoiding the use of critical raw materials (CRM), utilization of waste material and ensuring sustainability of the whole process. Besides lowering the carbon footprint, the project will suggest dual clean hydrogen production (via hydrolysis and pyrolysis reactions) technology.

Expected Results:

- Novel catalyst structure, which positively influences the conditions of methane pyrolysis.

- Laboratory validated pyrolysis process technology, where the most suitable parameters will be clarified.

- Method, that based on plasma treatment for regeneration of deactivated catalyst.

- Technology where the carbon-based thick film will be used as the working electrode for detection of pesticides.

Tasks at ISSP UL:

- Pre- and after treatment catalyst and carbon material analysis.

- Creation of a system for the pyrolysis process and gas analysis.

- Pyrolysis experiments and analysis of the composition of the resulting gases.

- Creation of pyrolysis reactor and overall system model.

- Communication and dissemination.

PROJECT PROGRESS INFORMATION

Period 01.06.2023. – 31.12.2023.

Milestone 1 reached

Design of the experimental set-up and gas line for methane decomposition

The experimental set-up is designed for the catalytic decomposition of methane into hydrogen and carbon under elevated temperatures within a controlled reactor environment. The gas line configuration allows the systematic collection of samples and safe storage of the produced hydrogen, contributing to a comprehensive study of the impact of catalyst and temperature on reactions and physical processes.

|

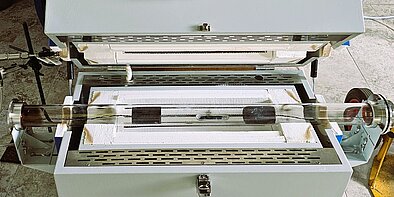

Reactor Design:

The quartz tube test reactor (OD 60 mm, length 1000 mm, heating length 440 mm) is a controlled air-less environment where a methane undergoes decomposition in the presence of a catalyst. It is compatible with high-temperature conditions and equipped with precise temperature control mechanisms to ensure a stable and reproducible experiments.

Temperature Control:

Precise temperature control is maintained within the reactor to ensure optimal conditions for methane decomposition. This is achieved through a combination of heating elements and K type thermocouples. Heater working temperature can reach 1200℃ with a precision of +/- 1℃ with a heating range 10℃/min.

Catalyst Integration:

A Fe/Ni catalyst deposited on gamma alumina support is introduced into the reactor in quartz cruicible to facilitate and enhance the methane decomposition process.

Gas Line Configuration:

Before starting the experiment, the system is purged to remove any residual air. Methane is then introduced into the reactor and subjected to controlled heating for temperature optimization, crucial for efficient methane decomposition into hydrogen and carbon. Post-decomposition, the gases flow through the integral gas line, which splits into two paths. One path directs gases to a sample bag for analysis, enabling the determination of reaction products, while the other stores hydrogen/gases for future use.

Period 01.11.2023 – 30.04.2024.

Deliverable D.3.1. completed

The implementation of an experimental set-up and gas pipeline for clean hydrogen production via methane pyrolysis is completed. Based on in Milestone 1 developed design, updated model is elaborated including purchased tubular oven and adjusted gas line to ensure efficient system operation.

All necessary equipment components to install tubular oven with heat regulation, gas line and sample gathering port were procured according to the project plan. The real system was installed following the updated design guidelines, with close attention to easy to use and safety considerations.

Comprehensive testing procedures were conducted to verify the functionality and integrity of the gas line and experimental set-up. With the upgraded experimental set-up and gas line in place, experiments are now being performed with confidence and success. The system operates smoothly and initial results indicate promising outcomes, ensuring further experiments and research in methane decomposition.

Period 01.01.2024. – 30.06.2024.

Milestone #3.3 reached

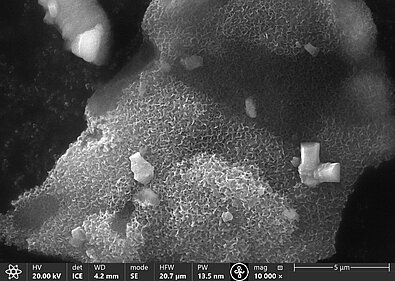

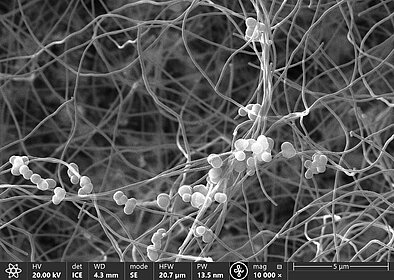

GATHERED MATERIAL AFTER THE PYROLYSIS REACTION

A series of methane pyrolysis experiments was conducted using an iron/nickel (Fe/Ni) catalyst distributed on gamma-alumina in a previously designed and constructed setup. The aim of this milestone was to evaluate carbon accumulation on the catalyst and to perform post-reaction material separation and collection for further experiments.

The pyrolysis reaction was performed in a vacuum-sealed quartz tube. Material was placed in a quartz boat within the reactor, fitted with heat stoppers, and methane gas was introduced. Methane was introduced at a pressure of 0.5 bar, with the system heated from room temperature to 800°C over 30 minutes and held at 800°C for 240 minutes, followed by natural cooling post-reaction.

Comparing initial catalyst mass with a post-pyrolysis catalyst mass, averagely 25% increase in total mass was observed. After pyrolysis carbon-coated catalyst was placed in a water and alcohol solution, sonicated for 5-10 minutes, and filtered using vacuum filtration. Unfortunately it was possible to gather only averagely 20% from formed carbon. The gases produced during pyrolysis were collected and analysed using gas chromatography-mass spectrometry for identification and composition assessment. After series of experiments main post-pyrolysis gasses were hydrogen (reaching 42%), methane, carbon dioxide, carbon monoxide, and water vapour.

The pyrolysis of methane over an Fe/Ni catalyst led to a hydrogen and solid carbon formation confirming the effectiveness of the catalyst and basic reaction conditions. Improvements to the separation process are needed to optimize carbon gathering and minimize catalyst contamination. Further adjustments to filtration methods, along with precise determination of optimal reaction temperature and duration, will be conducted to enhance both the yield and purity of the final products.

Period 30.04.2024. - 30.09.2024.

Milestone #3.2.1 reached

CARRIED OUT PYROLYSIS REACTION AND IDENTIFIED BASE TEMPERATURE

Two series of pyrolysis experiments were conducted to determine the optimal base temperature for methane decomposition over a catalyst. The initial experiments were carried out in a thermogravimeter (SETARAM Labsys Evo TGA/DSC) to accurately measure weight changes in the catalyst and deposited carbon throughout the pyrolysis process. This precise control allows for monitoring the thermal stability and decomposition behaviour of methane over the catalyst, providing essential insights into reaction kinetics and temperature-dependent behaviour. By establishing a detailed understanding of these variables, the thermogravimetric analysis helps to confirm the optimal base temperature and assess catalyst performance under controlled conditions before scaling up in the custom-built reactor.

After the thermogravimetric experiments were performed in a custom-built pyrolysis reactor, where methane was introduced at an inlet pressure of 0.5 bar not to breake quartz tube. Temperature gradually increased from room temperature to various target temperatures between 500°C and 1000°C over a 30-minute period. The system was then held at the target temperature for varying durations, ranging from 240 to 480 minutes, before allowing it to cool naturally post-reaction.

Experimental data analysis revealed that the optimal base temperature, achieving the highest yield, was 800°C. This finding indicates that the catalyst is active at this temperature and successfully promotes methane decomposition. These initial experiments helps to execute further studies, focusing on optimizing other pyrolysis parameters to improve efficiency and product yield.

Period 01.06.2024. - 30.09.2024.

Deliverable #3.2. completed

TRANSFERRED MATERIAL TO LEI AND JSI

The initial pyrolysis experiments established the optimal temperature, achieving milestone MS3.2.1. Using this data, an experimental methodology was developed and refined through further experiments, resulting in a reliable process for methane decomposition

Pyrolysis Experiment Methodology

- Preparation of Quartz Tube: Before the experiment, an Al₂O₃ or quartz sample boat is placed in the quartz tube and heated at 800°C for at least 2 hours to remove any potential contaminants or carbon residues.

- Weighing the Catalyst: The cleaned boat is weighed with 0.2-0.4 g of catalyst.

- Positioning the Boat: The boat is positioned centrally in the quartz tube, with Al₂O₃ stoppers placed at both ends to block heat transfer.

- Sealing the Tube: The quartz tube is sealed with stainless steel caps, one end connected to a methane cylinder and the other to a vacuum pump and gas sampling cylinder.

- Vacuum Creation: All valves are opened, and the vacuum pump is activated to create a pressure of 10-2bar.

- Isolating the Vacuum: The vacuum pump is turned off, and the vacuum valve is closed.

- Methane Introduction: Methane is introduced into the quartz tube to achieve a pressure of approximately 0.5 bar.

- Temperature Programming: The furnace controller is programmed to achieve the necessary temperature and time parameters, initiating the experiment.

- Cooling and Sampling: When the program ends, the furnace is allowed to cool to 350°C, after which the gas sampling valve is opened to collect a sample for mass spectrometry.

- Further Cooling and Pressure Equalization: The furnace is cooled to room temperature, and pressure in the tube is equalized by opening the sample valve without the gas sample cylinder.

- Sample Collection: The boat with reacted catalyst is removed, placed in a container, and weighed.

- Sample Analysis: The sample is sent for further analysis and, if necessary, is provided to collaborators.

Following these experiments, materials were transferred to LEI for catalyst regeneration and to JSI for electrode preparation for sensor integration. This procedure will continue to be refined as needed, after receiving an additional synthesized materials from LEI to further optimize and validate the methodology.

Period 01.09.2024. - 31.05.2025.

Innohyppy meeting with industry representatives

On September 5-6, 2024, Ainārs Knoks, a researcher from the InnoHyppy project, participated in the European Hydrogen Valleys Investment Forum, networking with industry representatives interested in hydrogen technologies and the hydrogen economy, including Dinex, Orleon, Latvenergo, and others. During the discussions, the role of turquoise hydrogen and the InnoHyppy project results in the industrial energy transition were emphasized, along with their potential in the hydrogen value chain.

The overall meeting provided insights into technology development, market adoption challenges, and sustainability, particularly in sectors such as transport, energy storage, and industrial applications, highlighting opportunities for collaboration and innovation, reinforcing the growing importance of low-emission hydrogen solutions in the industry’s life cycle.

Period 12. - 14.05.2025.

Deliverable: Partners meeting on Month 24

InnoHyppy partners meeting in Riga

On May 12-14, 2025, the Institute of Solid State Physics, University of Latvia (ISSP UL) hosted the consortium meeting of the InnoHyppy project. The three-day meeting brought together researchers from the Lithuanian Energy Institute (LEI), ISSP UL, and the Jožef Stefan Institute (JSI, Slovenia) to discuss recent scientific results, upcoming publications, and open questions related to project implementation.

Key topics included progress reports and planning for all work packages and hands-on experiments. A special activity was organized, during which catalysts synthesized by LEI were prepared and tested together with partners. Additionally, carbon materials obtained from the pyrolysis process were analysed before being sent to JSI for the fabrication of pesticide sensors.

The program was brightened up with a guided tour to ISSP’s laboratories, and a cultural excursion to Riga’s renowned Art Nouveau district, fostering both scientific exchange and international collaboration.