InCoatBat project advances lithium-ion battery technology with an innovative coating method

The InCoatBat project continues to pave the way for advancements in lithium-ion battery technology with the recent publication “Wet-Chemical Synthesis of a Protective Coating on NCM111 Cathode: The Quantified Effects of Washing, Sintering and Coating” in an open-access scientific journal “Journal of the Electrochemical Society.” The article is co-authored by Līga Maskova and Gints Kučinskis (Energy Materials Laboratory (Institute of Solid State Physics, University of Latvia (ISSP UL), Reinis Ignatāns (Microscopy Laboratory, ISSP UL), Anatolijs Šarakovskis (Spectroscopy Laboratory, ISSP UL), Arturs Vīksna (University of Latvia), Māris Knite (Riga Technical University).

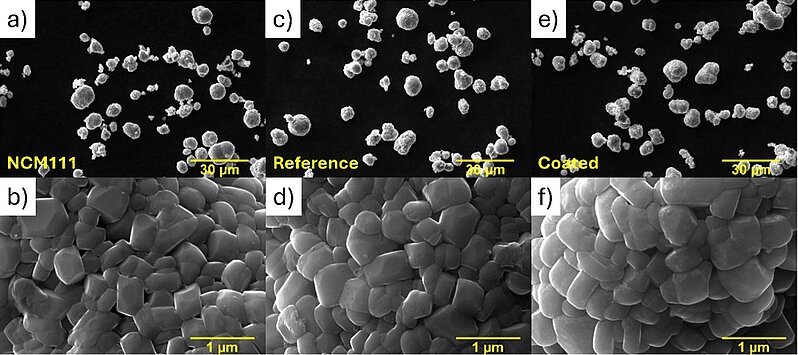

This study, supported by the M-Era.net project InCoatBat, focuses on a sustainable wet-chemical method to enhance the performance of NCM111 cathode materials. The research team investigated the application of an aluminum oxide (Al2O3) coating on NCM111, aiming to improve the cycling stability of lithium-ion batteries. Through a detailed analysis of various treatment steps—including washing, sintering, and coating—the study quantified their individual contributions to enhancing performance.

The results were promising, revealing that the Al2O3-coated NCM111 maintained an impressive 88% of its initial capacity after 500 charge-discharge cycles. This significant improvement is attributed to the protective coating's ability to inhibit adverse reactions with the electrolyte and scavenge hydrofluoric acid (HF) generated during cell operation.

A key finding of the study is the critical importance of establishing a proper baseline for characterizing coated materials. The research demonstrated that simply washing and sintering the cathode material could not replace the benefits derived from the protective coating. The coated NCM111 consistently outperformed both untreated and merely treated samples in terms of capacity retention, showcasing the efficacy of the coating method in combating surface-based degradation and boosting battery performance.

This research not only highlights the vital role of the coating process in extending the cycle life of NCM cathodes—especially those with higher nickel content—but also offers valuable insights into improving the overall electrochemical performance of cathode materials.

As the InCoatBat project progresses, this innovative approach to coating NCM111 cathodes marks a significant step towards enhancing the longevity and efficiency of lithium-ion batteries, contributing to the ongoing pursuit of sustainable energy solutions.

The first results of the InCoatBat project are presented at the NordBatt 2024 conference

The 6th NordBatt conference, a leading forum for advancements in battery technology and sustainable energy solutions, took place September 24-27 in Oslo, Norway, showcasing pioneering research and innovations in the field. Among the invited speakers was Dr. Gints Kučinskis, the project coordinator of the InCoatBat project, representing the Institute of Solid State Physics, University of Latvia.

Dr. Kučinskis delivered an insightful presentation titled "Enhancing NCM111 Cathode Performance with Sustainable Al2O3 Coating via Ethanol-Based Wet-Chemical Synthesis." The research focuses on the challenges lithium-ion batteries face, particularly those utilizing LiNixCoyMn1-x-yO2 (NCM) cathodes, which are essential for improving energy density. Despite their potential, these high-nickel content cathodes often struggle with cycle life, a critical factor for commercial viability.

The presentation highlighted a novel, sustainable method for coating NCM111 cathodes with a thin aluminum oxide (Al2O3) layer using an ethanol-based wet-chemical synthesis approach. This method aims to address surface degradation mechanisms that compromise battery performance over time. Gints Kucinskis and his team conducted a thorough assessment of the impacts of washing, sintering, and coating on the electrochemical performance of NCM111 cathodes. Notably, the Al2O3-coated NCM111 exhibited remarkable cycling stability, retaining 88% of its initial capacity after 500 charge-discharge cycles. In contrast, the re-sintered samples maintained only 79%, while untreated samples showed a significant drop to 65%. The study emphasized that while sintering contributes to cycle life by regenerating the material and removing residual lithium compounds, the Al2O3 coating plays a crucial role in preserving the layered structure and inhibiting harmful reactions with the electrolyte.

At the NordBatt conference, the coordinator of the project not only presented the results of the research, which makes a significant contribution to the development of sustainable battery technologies but also participated in numerous discussions promoting cooperation between researchers and industry representatives.

NordBatt is a regional Nordic conference where the latest battery research is presented. More than 200 scientists and students from leading Nordic universities, research institutes and industry participated in the conference.

InCoatBat project launches, uniting global partners for innovative battery coatings

On July 25, the InCoatBat project (Inert Coatings for Prevention of Ageing of NMC Cathode for Lithium-Ion Batteries) kicked off online. The meeting was organized by the project’s coordinator, the Institute of Solid State Physics, University of Latvia (ISSP UL). Four partners from three countries set the stage for a collaborative initiative that spans the realms of academia and industry.

Representatives from the ISSP UL (Latvia), National Taiwan University (Taiwan), VARTA Microbattery GmbH and Center for Solar Energy and Hydrogen Research Baden Württemberg (Germany) came together to exchange ideas, share their expertise, and lay the groundwork for innovative coatings for lithium-ion batteries.

During the kick-off meeting, partners discussed the details of the project's work packages that focus on different aspects of the research. The academic partners will lead in materials synthesis and characterization, fundamental electrochemical understanding, and advanced structural analyses. The industry partners will bring their expertise in large-scale production and battery cell manufacturing. The meeting provided a unique platform for introductions, fostering a deeper understanding of the diverse skills and perspectives each partner brings to the table.

The discussions went beyond theoretical frameworks, delving into the practical aspects of collaboration. Partners engaged in fruitful dialogues, exploring the intricacies of cooperation and establishing a solid foundation for the shared journey ahead. The event's agenda facilitated the alignment of objectives for the success of the InCoatBat project.

The project's timeline spans over 36 months. The diverse and complementary skills of the consortium members ensure a comprehensive and strategic approach to achieving the project goals.

Stay tuned for updates on the progress and outcomes of the InCoatBat project as we work towards revolutionizing battery technology for a more sustainable future!

M-ERA.NET Call 2022 project InCoatBat launched to develop innovative surface coatings for lithium-ion batteries

The Institute of Solid State Physics, University of Latvia (ISSP UL), in collaboration with the National Institute of Chemistry (Slovenia), National Taiwan University (Taiwan), Center for Solar Energy and Hydrogen Research Baden Württemberg (Germany), and VARTA Microbattery GmbH (Germany) has officially launched the InCoatBat project under the M-ERA.NET Call 2022.

The project's main objective is to develop inert protective coatings that significantly extend the service life of LiNi0.83MnxCo0.17-xO2 (NMC Ni83) cathode for lithium-ion batteries (LIBs) based on a deep quantitative understanding of the underlying physical and electrochemical phenomena of electrode aging and its mitigation.

State-of-the-art batteries are moving in the direction of high Ni NMC materials, such as NMC Ni83. However, the increased energy density of Ni83 comes at the cost of lower cycle life. This innovative project aims to address the challenges of premature degradation of state-of-art cathodes in Li-ion batteries by developing protective surface coatings using easily scalable chemical and magnetron sputtering approaches. The consortium, consisting of academic institutions and industry partners, will work collaboratively to advance an innovation from fundamental research to pilot scale, demonstrating full high energy Li-ion battery cells with improved service life.

"We are excited to lead the InCoatBat project, which promises to bring significant advancements to the field of lithium-ion batteries," said Dr. Gints Kučinskis, project coordinator at the ISSP UL. "By developing innovative protective coatings, we aim to create high energy Li-ion battery materials with longer cycle life, contributing to a more sustainable use of resources and energy."

The InCoatBat project is set to span three years, with a total budget of EUR 2,515,200. Under the coordination of the Institute of Solid State Physics at the University of Latvia (ISSP UL), this collaborative initiative aims to harness cutting-edge research and technological advancements to revolutionize lithium-ion battery performance. Together, the consortium will pave the way for sustainable energy solutions by delivering innovative coatings that enhance battery longevity and efficiency.