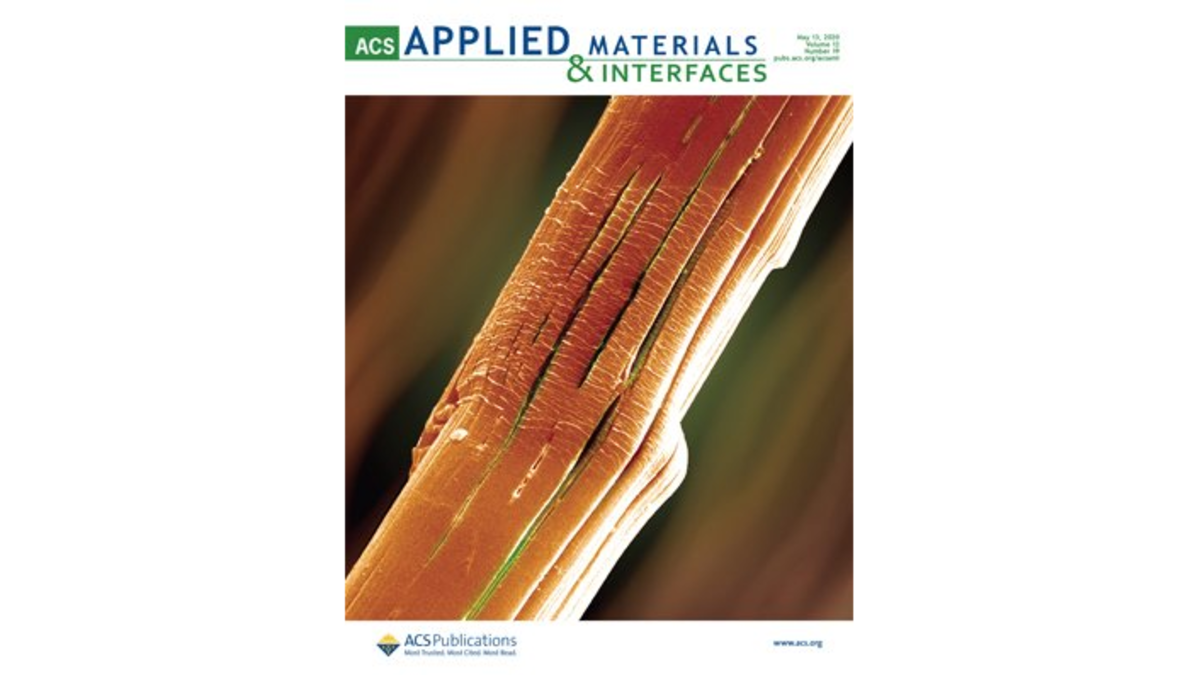

To better understand the structure of high performance fibers found in body armor and aerospace engineering, imagine red licorice candy and the way it is usually eaten – by pulling and peeling it. This also could describe a powerful new technique for analyzing and hopefully ultimately combating the failure of the polymer fibers.

The bottleneck since the 1980ties was a limited grasp on how fibers behave when getting stretched to their breaking point. Yuris Dzenis, McBroom Professor of mechanical and materials engineering, and the U.S. Army collaborators think that it might be due to the poor understanding of how these complex fibers respond to loading. Though researchers had analyzed how fibers respond on the nano- and macroscale, none had figured out how to measure the interactions among the microscopic bundles.

They used a technique that was nanoscopic equivalent of walking a tightrope without disturbing it. The resulting data, and the technique that yielded it, should inform future computational models and eventually help optimize manufacturing processes that lead to more-resistant, longer-lasting fibers, the researchers said.

Yuris Dzenis, Stockdale and Nebraska postdoctoral researcher Dimitry Papkov authored the study with the U.S. Army Research Lab’s Kenneth Strawhecker, Daniel Cole, Jeffrey Staniszewski, Michael Roenbeck and Steve Lustig. The team received support from the Army Research Lab, the National Science Foundation, the Office of Naval Research, the National Institutes of Health and the Nebraska Center for Energy Science Research.

Please read this full article by Scott Schrage, University of Nebraska-Lincoln